Last year, we launched the Hi Tour Shenzhen Manufacturing Journey for the first time, and every participant returned with a wealth of knowledge! This year, we will continue this tradition to enable more friends to personally experience the intelligence, digitalization, and efficiency of modern factories!

In the upcoming Hi Tour, we will guide participants to closely observe the practical operations in manufacturing processes, production efficiency, and quality control, allowing you to experience the charm of high-tech equipment and smart manufacturing technologies firsthand. Meanwhile, we will also provide professional commentary to help you gain deeper insights into modern manufacturing operations and the future prospects of “Made in China.”

Whether you’re a maker or an industry professional, we hope the Hi Tour will inspire new ideas and help you discover the endless possibilities behind technology!

Event Name: Hi Tour

Event Date: November 18, 2024

Event Type: Factory Tour

Organizer: Seeed Fusion Team

Itinerary:

- 8:30 Gathering

- 9:30-12:00 Visit Seeed Agile Manufacturing Center

- 12:30-14:00 Lunch

- 14:30-16:30 Explore 3D Printing Factory

- 17:30 Return to Gathering Point

Registration Period: October 16 – November 6, 2024

Date of Event: November 18

Pick-up and Drop-off Location:

Design Commune, Vanke Cloud City, Xili Street, Nanshan District, Shenzhen

Cost: $35 per person (excluding lunch) / $43 (including lunch)

Capacity: 40 participants

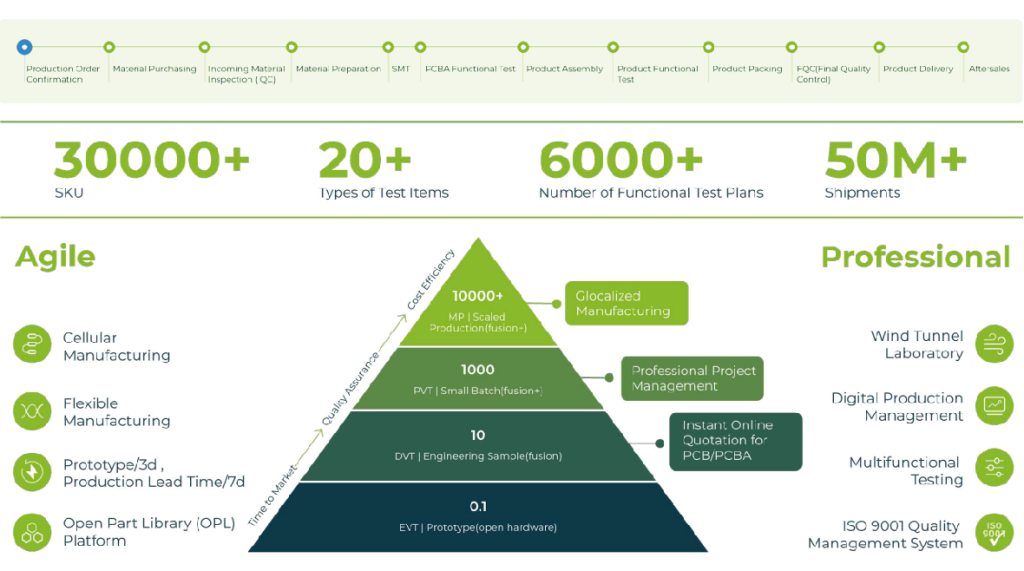

Seeed Agile Manufacturing Center

The Seeed Agile Manufacturing Center provides comprehensive and professional production management services for global customers through efficient production manufacturing, professional warehousing operations, and an advanced wind tunnel laboratory.

Seeed Fusion Produce turns designs into solid products from 1 to 10,000+! With expertise in electronics, mechanical engineering, packaging, and certification, we ensure top-notch quality at every step in the supply chain and manufacturing. Whether it’s a small or large-scale production, we offer efficient fulfillment to bring your vision to life and exceed your expectations.

Highlights:

1. Agile, Professional, and Flexible Manufacturing: The factory focuses on cellular manufacturing to meet diverse product requirements. The cellular manufacturing model enables agile switching and adjustment with greater flexibility to meet varied market demands.

2. Wind Tunnel Laboratory: Equipped with advanced tools and technology for various wind tunnel experiments, including wind speed, wind direction, and structural fluid dynamics experiments, and allows for simulation tests to evaluate and verify product performance.

3. Digital Production Management: The Seeed Factory embraces digitalization and adopts digital production management systems to enhance capacity and efficiency. By integrating sensors and automation equipment, it monitors various metrics in real-time throughout production, ensuring stable data transmission and the prompt detection and resolution of anomalies.

4. Multifunctional Testing: Through mold testing demonstrations, you can observe technicians operating various equipment for testing and evaluation, deepening your understanding of our jig testing processes for better insights into product quality and production efficiency.

3D Printing Factory

Highlights:

1. Advanced 3D Printing Equipment: Explore different types of 3D printing equipment, understanding their operating principles and applicable materials.

2. Production Line Management: Tour the complete 3D printing process, from design, printing, and post-processing to final quality inspection, gaining insights into each stage’s craftsmanship.

3. Custom Production: Learn how to achieve desired products through 3D printing and how Seeed Fusion’s customization services integrate with 3D printing.

4. Post-processing and Quality Control: Observe the post-processing steps after product printing, with introductions to the factory’s quality control system and management processes, ensuring excellent printing precision and material strength and toughness.

Co-create Star Project Showcase

Seeed Fusion offers a series of hardware customization services, from prototype to produce and promote. Since its establishment in 2009, Fusion has been serving thousands of clients with roughly ten thousand orders per month. Dedicated to helping clients achieve leaps from 0 to 100 and beyond, Fusion collaborates for co-create and growth! This tour will feature special showcases of popular Co-create projects, illustrating how Seeed Fusion assists users from initial production to mass customization, and promotion.

Through this Hi Tour, you will gain:

– A close understanding of Shenzhen’s manufacturing technologies, experiencing the operation of advanced equipment.

– Insight into the operation of smart factories in Shenzhen, learning how data and technology enhances production and management efficiency.

– Opportunities to interact with participants worldwide, catching up with the latest developments and trends in the manufacturing industry, and possibly expanding collaboration opportunities.

– Enhanced technical and industrial knowledge through hands-on visits and experiential learning.

How to Register:

Click here or scan the QR code below to secure your spot!